Leveraging Analytics in 3PL Warehouse Operations: A Game-Changer for Efficiency and Growth

Third-party logistics (3PL) providers are constantly seeking ways to optimize their warehouse operations. One of the most powerful tools at their disposal is analytics. By harnessing the power of data, 3PL warehouses can transform their operations, boost efficiency, and drive growth. Let’s explore the key benefits of implementing analytics in 3PL warehouse management.

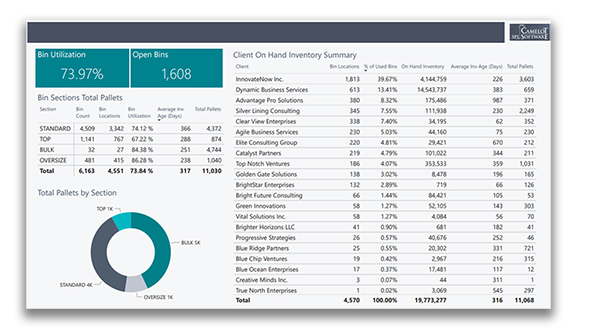

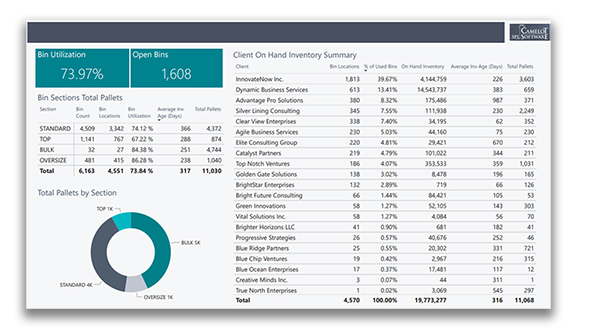

1. Enhanced Inventory Management

Analytics provides real-time visibility into inventory levels, allowing 3PL providers to:

- Optimize stock levels

- Reduce carrying costs

- Minimize stockouts and overstock situations

- Improve demand forecasting accuracy

By leveraging predictive analytics, warehouses can anticipate demand fluctuations and adjust inventory levels accordingly, ensuring optimal stock at all times.

2. Improved Operational Efficiency

Data-driven insights enable 3PL warehouses to streamline their processes:

- Identify bottlenecks in workflows

- Optimize picking and packing routes

- Enhance labor allocation

- Reduce order processing times

By analyzing historical data and current trends, warehouses can make informed decisions to boost overall operational efficiency.

3. Better Resource Allocation

Analytics helps 3PL providers make smarter decisions about resource allocation:

- Optimize warehouse space utilization

- Improve equipment usage

- Enhance workforce scheduling

- Reduce energy consumption

These improvements lead to cost savings and increased productivity across the board.

4. Enhanced Customer Service

By leveraging analytics, 3PL warehouses can significantly improve their customer service:

- Provide real-time order tracking

- Offer more accurate delivery estimates

- Quickly identify and resolve issues

- Personalize services based on customer preferences and behavior

This data-driven approach to customer service can lead to increased customer satisfaction and loyalty.

5. Proactive Risk Management

Analytics enables 3PL providers to identify potential risks before they become major issues:

- Detect patterns that may indicate equipment failure

- Identify safety hazards in warehouse operations

- Forecast potential supply chain disruptions

- Mitigate inventory shrinkage and loss

By addressing these risks proactively, warehouses can avoid costly downtime and maintain smooth operations.

6. Continuous Improvement

Analytics provides the foundation for a culture of continuous improvement:

- Set and track KPIs

- Identify areas for improvement

- Measure the impact of process changes

- Benchmark performance against industry standards

This data-driven approach to improvement ensures that 3PL warehouses stay competitive in a rapidly evolving industry.

Conclusion

Implementing analytics in 3PL warehouse operations is no longer a luxury—it’s a necessity for those looking to thrive in today’s competitive logistics landscape. By leveraging data to enhance inventory management, improve operational efficiency, optimize resource allocation, boost customer service, manage risks proactively, and drive continuous improvement, 3PL providers can position themselves for long-term success and growth.

As technology continues to evolve, those who embrace analytics will find themselves at the forefront of the industry, ready to meet the challenges and opportunities of tomorrow’s supply chain demands.