Navigating the Depths of Data Analytics: Unveiling 4 Levels in a 3PL Warehouse

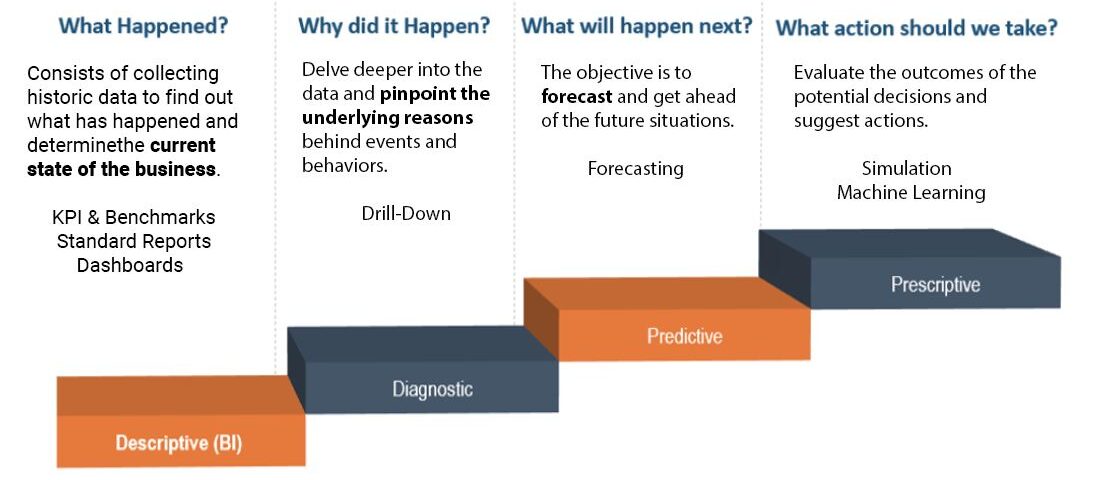

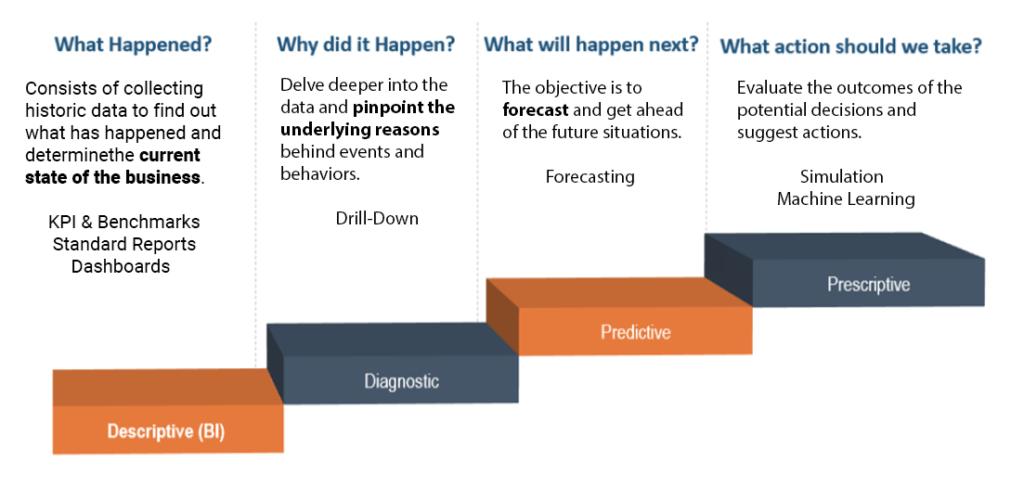

The ability to extract meaningful insights from data is crucial. This is where data analytics and reporting come into play, offering a comprehensive understanding of operations and paving the way for strategic decision-making. In the realm of 3PL warehousing, we are focusing on four distinct levels of data analytics and reporting, each serving a specific purpose in unraveling the complexities of logistics. Let’s delve into each level to understand how they contribute to the optimization of warehouse operations.

The 4 Levels Explained

1. What happened?

The first level of data analytics in a 3PL warehouse involves understanding “What happened?” This level revolves around collecting historical data to discern the current state of the business. Key Performance Indicators (KPIs), benchmarks, standard reports, and dashboards are the tools used to shed light on past events and performance metrics. By analyzing these metrics, warehouse managers can gain insights into operational efficiency, identify bottlenecks, and assess overall performance against predefined benchmarks. This level sets the foundation for informed decision-making and continuous improvement.

2. Why did it happen?

Moving beyond the surface, the second level of data analytics aims to answer the question “Why did it happen?” Drill-down analysis is employed to dig deeper into the data and identify the underlying causes behind specific events and behaviors. This involves a more detailed examination of individual processes, transactions, and interactions within the warehouse. Understanding the root causes of issues enables proactive problem-solving and helps in preventing recurring issues. It’s a crucial step toward optimizing processes and enhancing overall warehouse efficiency.

3. What will happen next?

Anticipation is the key at the third level of data analytics in 3PL warehousing. “What will happen next?” is the question at the core of forecasting. By leveraging historical data and employing advanced analytics techniques, such as predictive modeling, warehouses can forecast future demand, identify potential disruptions, and anticipate resource requirements. Forecasting is instrumental in strategic planning, ensuring that the warehouse is well-prepared for upcoming challenges and opportunities. It serves as a proactive approach to managing resources and maintaining a competitive edge in the dynamic logistics landscape.

4. What action should we take?

The pinnacle of data analytics in 3PL warehousing involves answering the question “What action should we take?” This level goes beyond prediction and delves into prescriptive analytics. Simulation and machine learning are employed to evaluate the outcomes of potential decisions and suggest the most effective actions. Simulation models allow warehouses to test different scenarios and strategies in a risk-free environment, enabling them to make informed decisions without disrupting ongoing operations. Machine learning algorithms, on the other hand, continuously learn from data, providing adaptive insights for more accurate decision-making over time.

In summary, the four levels of data analytics and reporting in 3PL warehousing form a progressive journey from understanding past events to making informed and proactive decisions for the future. By harnessing the power of data at each level, warehouses can optimize operations, enhance efficiency, and stay ahead in the dynamic and competitive logistics landscape. As technology continues to evolve, the integration of advanced analytics and reporting tools will become even more critical for 3PL warehouses aiming to thrive in the era of data-driven logistics.